Publication | Poor Yaw Alignment: Beware of Losses!

A wind turbine is capable of continuously orienting itself towards the wind to maximize wind capture. It therefore rotates around its yaw axis ("yaw" in English). As soon as the alignment is not perfect, the turbine records a loss in potential gains. How much can this be estimated?

The technological feat of a wind turbine consists of moving a several-ton nacelle with several motors, to adapt to a wind direction that changes quickly and very randomly.

This movement is necessarily the result of a complex chain involving sensors, a control system, and an algorithm. Poor alignment may correspond to a turbine shutdown, a poorly configured regulation system, but it may also result from the inevitable inertia of alignment (which is accentuated in case of poor lubrication, for example), or from natural aging of the machine.

How to Detect Poor Yaw Alignment?

Although an alignment issue can be identified during a technical inspection on site, its detection from a distance and in real time is crucial.

Thanks to advanced data analysis, it is possible to predict, recognize, and quantify the deviation between the current position of the nacelle and its optimal alignment. This proactive approach allows for quick intervention to correct any deviations, thus minimizing performance losses and increasing the durability of the equipment.

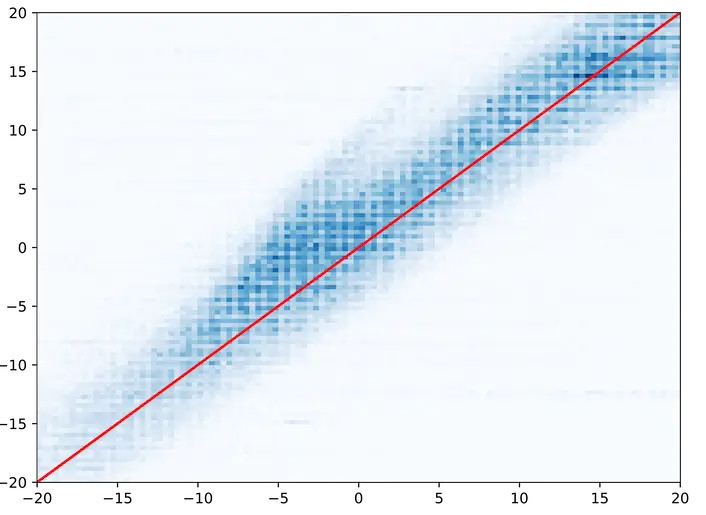

The graph on the right shows how to detect and analyze the gap between the wind direction angle (on the x-axis) and the nacelle orientation angle (on the y-axis) for a wind farm over 7 years of operation. The ideal situation would correspond to the red diagonal.

Any point outside this diagonal is a poor yaw alignment ("yaw misalignment"). This angular gap is sometimes significant, reaching nearly 15 degrees!

How to Quantify the Associated Losses?

The instant mechanical power when the directions of the nacelle and the wind are not aligned is reduced by a cosine factor of the yaw misalignment angle. It is therefore possible to quantify the instant and total loss due to yaw misalignment, as well as the part of the machine's underperformance that must be attributed to it.

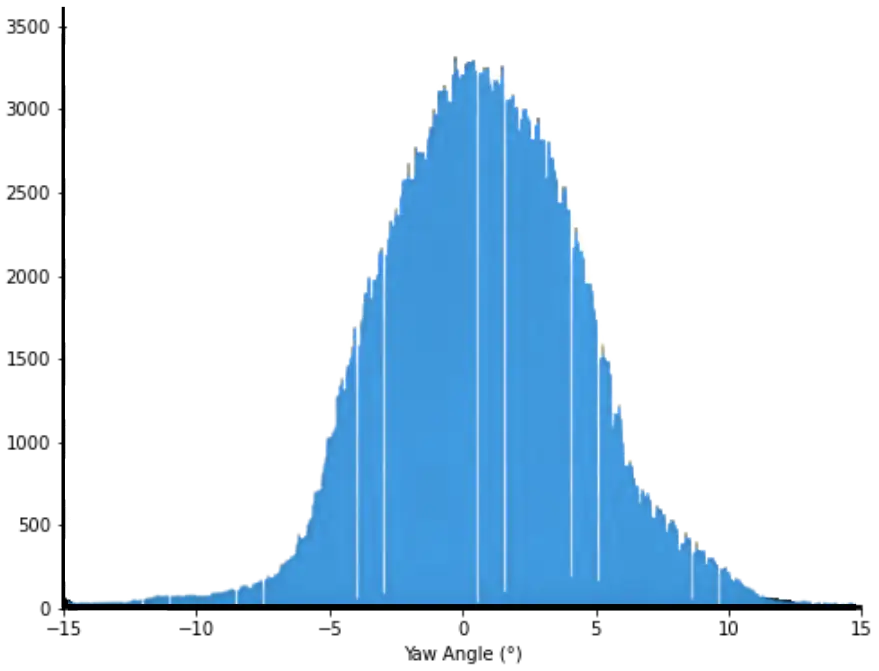

Beyond the losses, it is interesting to characterize in more detail the characteristics of this misalignment. It is not uncommon for it to be asymmetrical, as shown by the graph on the right, where you can see how the values of misalignment are distributed.

This is the starting point for our more advanced analyses towards finding the origin of the misalignment.

Going Further

With WindDeep, you can specifically follow in real-time the proper alignment of the yaw of each wind turbine in your wind farm.

You can also request a diagnostic report, in the form of an audit report, for a period of your choice, on the underperformance of your turbine in terms of yaw alignment or the sub-optimization of the yaw regulation system, as well as an estimate of the associated losses. A more in-depth analysis of the alarms allows tracing back to the origin of the poor alignment.

@2024 Winddeep. All rights reserved. Olivier Ky Thiêp Choffrut-Phan.